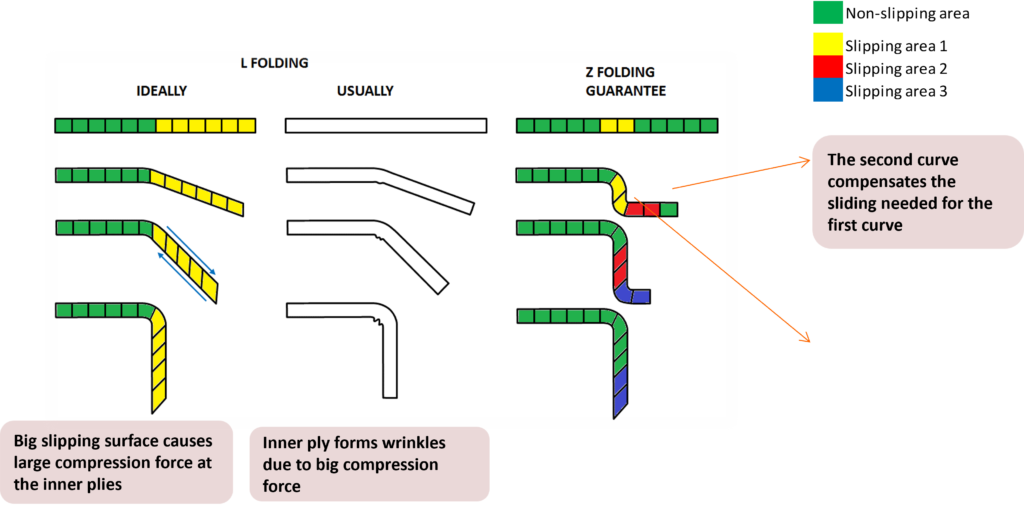

The folding of a full-thickness charge implies a high amount of compression forces in the inner side of the radius that could produce a longitudinal wrinkle in this area. The reduction of the viscosity when the charge is heated is not enough to mitigate this problem most of the time.

GLIDE forming processes uses the Z-folding to increase the sliding capability of the layers in the transversal section producing the Book-End effect in the edge of the part.

The Z-folding reduces the sliding area and compensate the sliding compression in the inner plies by gradually folding a small portion of the section.